CNC - milling and engraving of plastics, shape machining of plastics

PLEXIPLAST - precision in every detail.

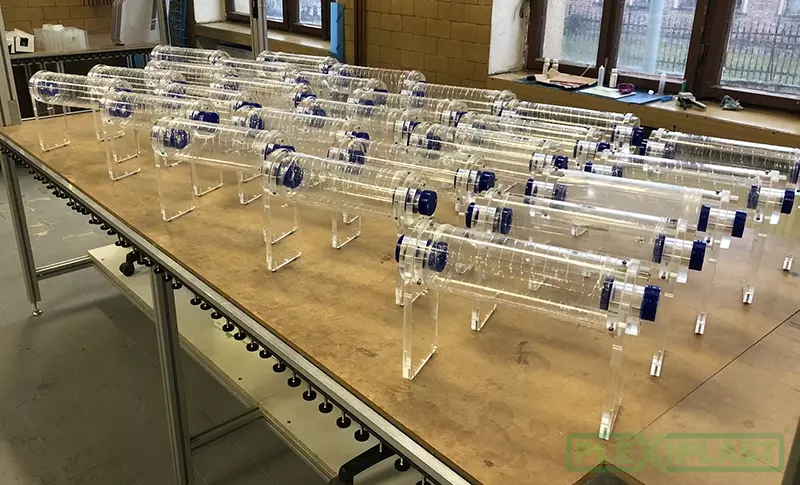

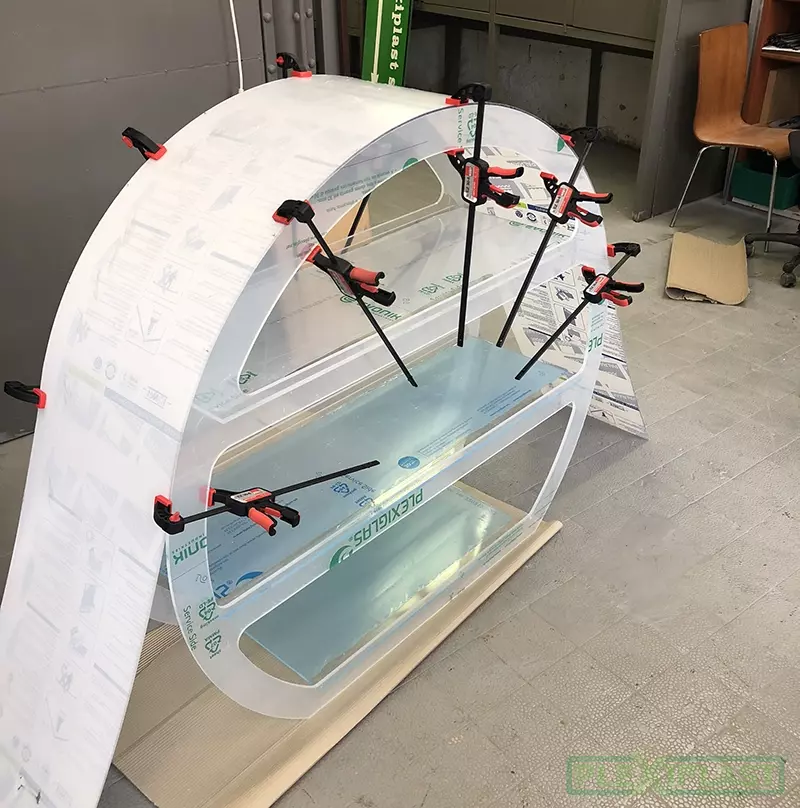

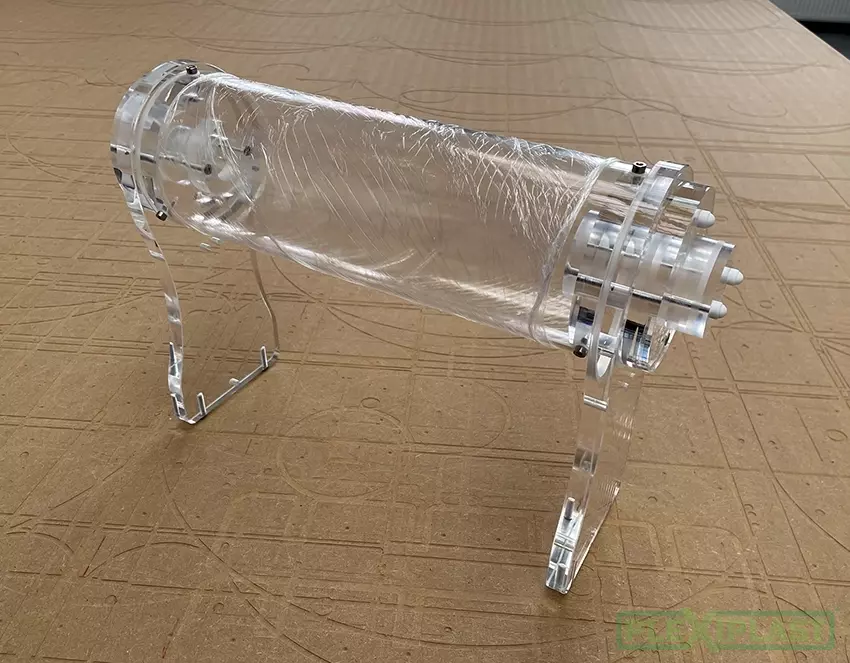

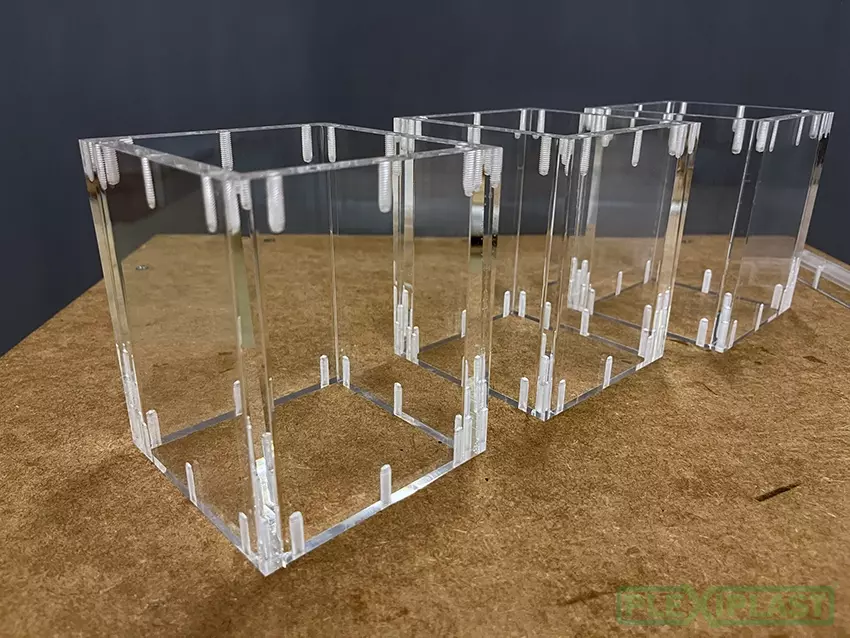

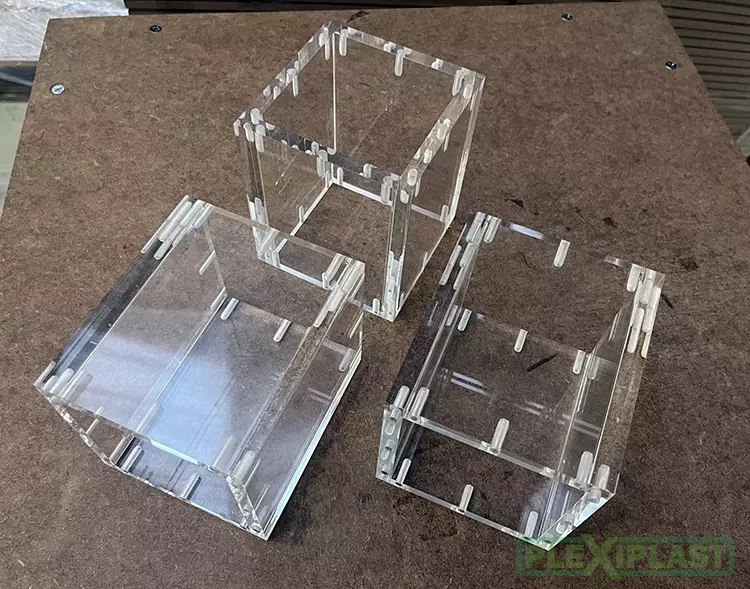

At Plexiplast s.r.o. we specialize in CNC machining of plastic materials, especially plexiglass (PMMA), polycarbonate and other plastics. Thanks to many years of experience and modern technologies, we offer high-precision milling of customized parts - from prototypes to mass production.

What materials are milled most often?

- PMMA (plexiglass - acrylic) - Technical components, illuminated signs and design elements.

- PC (polycarbonate - full, hollow) - Suitable for protective covers and safety features.

- PETG- High chemical resistance, often used in food and medicine.

- Bond (composite) plates - aluminium sandwiches Dibond, Alucobond

- PVC - Strong and durable material, great for building components, insulation boards and pipes.

- PE (polyethylene) and PP (polypropylene) - Lightweight and chemically resistant plastics, easy to weld.

- Technical plastics - PA (polyamide/nylon), PA6, POM (derlin), PE-HD, PE500, PE1000.

- HPS - hardened polystyrene.

- HPL boards - high pressure laminate Fundermax, Crown.

Why cooperate with PLEXIPLAST?

PLEXIPLAST - precision in every detail.- Our many years of experience make us one of the market leaders in Europe.

- Our own production - everything is handled directly by us, without intermediaries.

- Flexibility - small and large series, prototypes and custom solutions.

- Quality - consistent output control.

Typical orders

- Covers and protective elements

- Technical parts for engineering

- Advertising boards and cut-outs

- Design and architectural elements

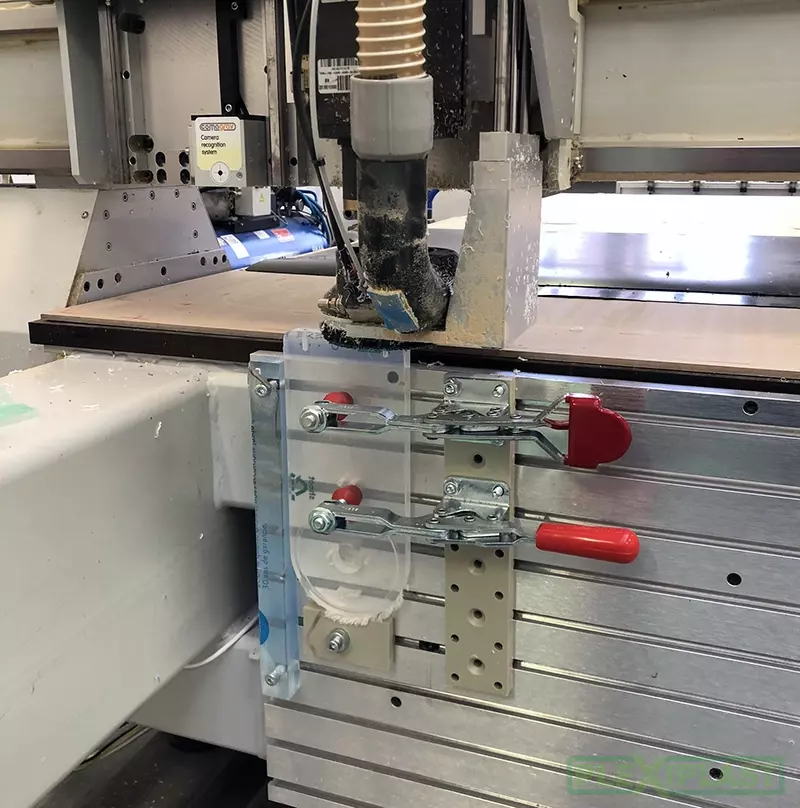

Use of CNC router for plastic milling:

PMMA milling of Plexiglas (acrylic)

Plexiglas milling enables precise shape machining of acrylic and production of complex shapes and patterns. The milling machine also enables machining of a wide range of materials, including milling of plastics, polycarbonate, PVC, ABS, MDF, DTD, AL.

Plastics milling advantages:

- even materials that can not be laser cut can be milled

- technologically better edge quality (compared to laser cutting)

- possibility of edge machining of materials on a vertical T-slot table

- possibility of polishing surfaces and edges with special diamond tools

Milling of the side edges of the material:

CNC router contour engraving of Plexiglas

Engraving is basically engraving with a special tool (pointed) into the material. When engraving on Plexiglas, a shank cutter is usually used, which either separates the material or machined to the desired depth. In both cases, this is classic chip machining.

Milling of plastics

Milling of transparent plastics:

Composite and other plastics

- Aluminium sandwich plates

- MDF and DTD boards

- Dibond, ACP bond i

- Hardened plastic ITEM

- ABS - Umastir ABS

- HPS - High-strength polystyrene (HIPS boards)

Structural and industrial plastics:

- Polyethylene PE

- Polypropylene PP-C, PP-H

- PVC polyvinyl chloride

- Forex, Foamalux, PVC strips

- POM-C (polyamides)

- Teflon PTFE

- PA, silon PA6 (polyamides)

Technical Advisor

Contact our experienced technical advisor to find out all about the prices and processing options for the materials listed

BY PHONE

VIA EMAIL