Production of hemispheres and lenses

Plexiglas hemispheres, domes, lenses, canopies of different colours

Hemispherical blow molding (Plexiglas blow molding) is a specialized manufacturing process in which we shape a plastic material - most commonly Plexiglas (PMMA) - into the exact shape of a hemisphere or lens using heat and pressure. We use this processing method to produce design and engineering elements with a wide range of applications across industries.

We offer both piece and mass production:

- plexiglass lenses, canopies

- plexiglass hemispheres - from 0.2m diameter up to larger sizes of 1.8m diameter)

- plexiglass domes or plexiglass cupolas

- Plexiglas skylights

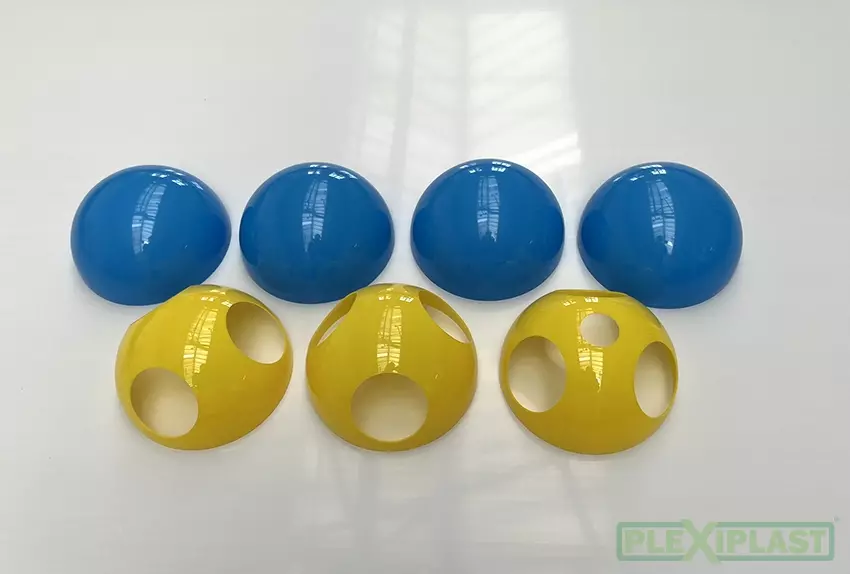

Acrylic spheres production

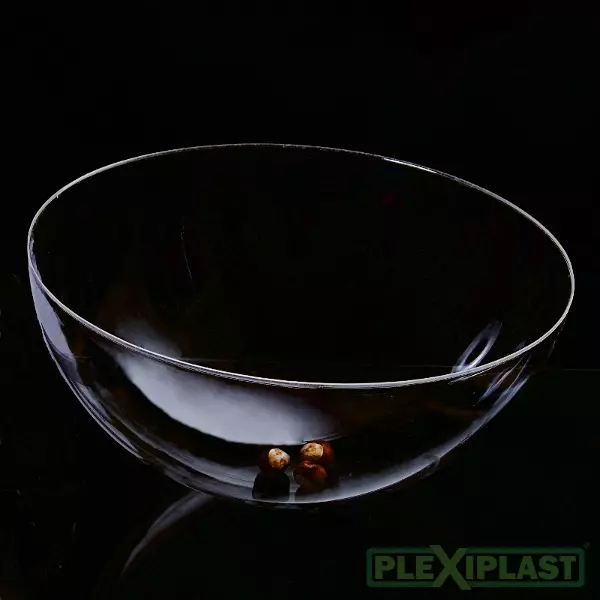

Both hemispheres and lenses are available with or without hem. The diameter of the hemisphere is according to the customer's request. We are able to blow diameters from 200 mm to 1800 mm, the thickness of the material used in the blowing is 3-8 mm. The thickness of the material is always less at the top than the hem material.

Spheres, domes (lenses) can be connected into ball. Seams are visible and for greater stiffness adhesive or bolts are used to connect together two spheres on the rims.

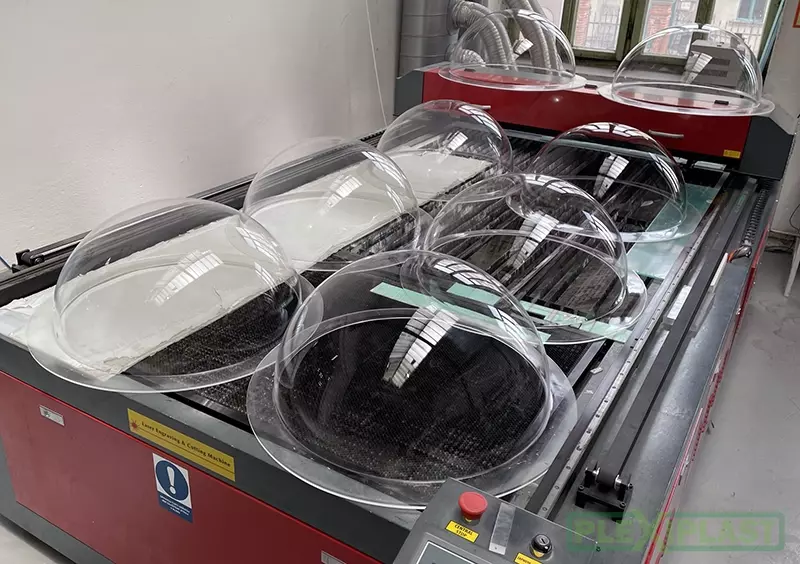

Examples of clear plexiglass hemispheres and lenses

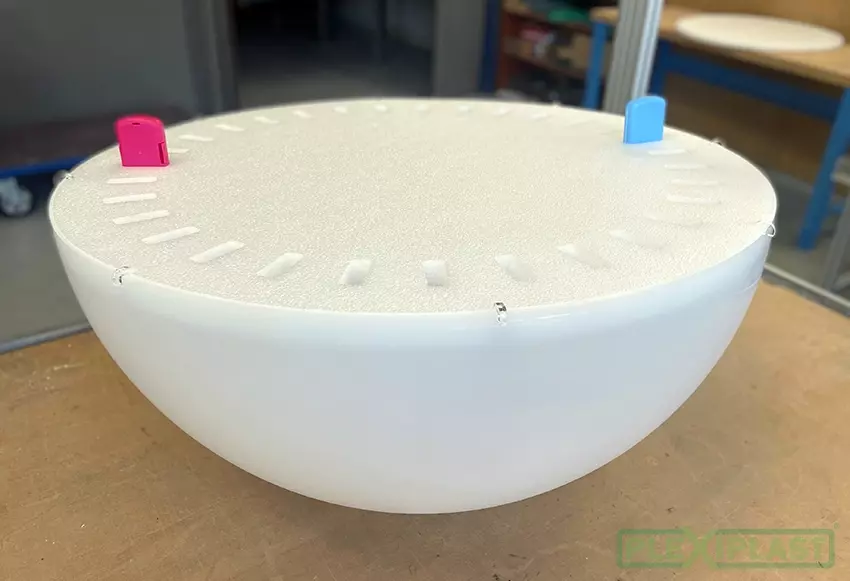

Opal plexiglass domes, product stands

Opal plexiglass domes, product stands

Technical Advisor

Contact our experienced technical advisor to find out all about the prices and processing options for the materials listed

BY PHONE

VIA EMAIL