Bonding of Plexiglas and other plastics

Gluing of Plexiglas means permanent connection of individual Plexiglas parts by means of a chemical substance (glue) which temporarily disturbs the structure of plastics and after drying creates a solid, unbreakable joint of materials. We are concerned with the bonding of plates in the surface (layering of plates of material on top of each other) and the bonding of edges to the surface of the plate (bonding in the edge of the material).

Options for bonding plexiglass edges:

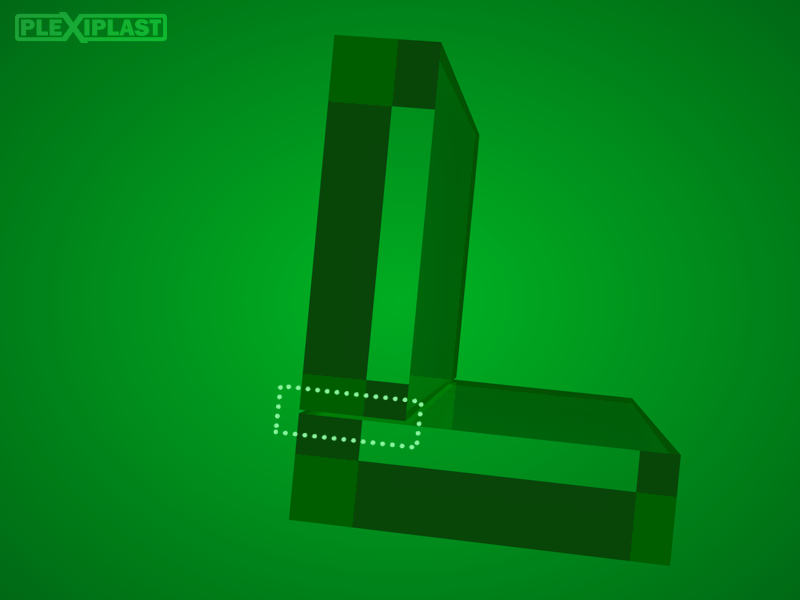

Butt joints gluing

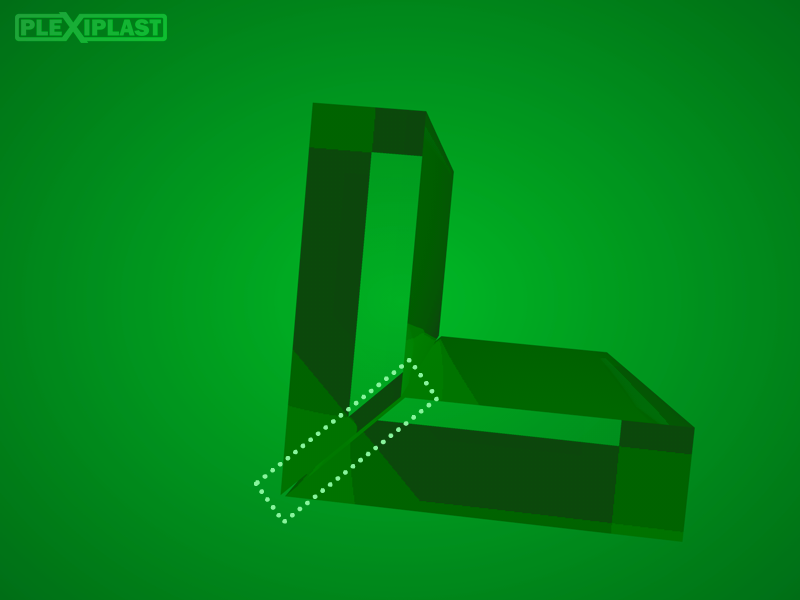

Gluing at 45°

Both of these two options for bonding the boards can be used with one-component or two-component adhesive. The application of the two-component adhesive is more complicated, but the bonded joint has higher strength, clarity and no bubbles. By using a two-component adhesive, the bonded joint is so perfect that it is impossible to tell whether the object was glued butt or mitre.

Technologické porovnání použitých lepidel:

One component adhesive gluing

Basic type of glued joints in quotations- The cheaper and more common way of gluing edges

- Contains a certain amount of visible bubbles

- A quick and efficient way

- The most commonly used

- Basic glue in quotations

- Possibility of gluing edges and surfaces of material boards

Two-component adhesive gluing

Technologically, time-consuming and financially more demanding bonding of Plexiglas.- A more expensive bonding method

- The glued joint does not contain bubbles

- Visually higher quality bonded joint

- Higher strength of the bonded joint

- Technologically and time consuming

- Price of glued joints on request

- Requires precise preparation, experience and skill of the worker

- Possibility of gluing edges and surfaces of material boards

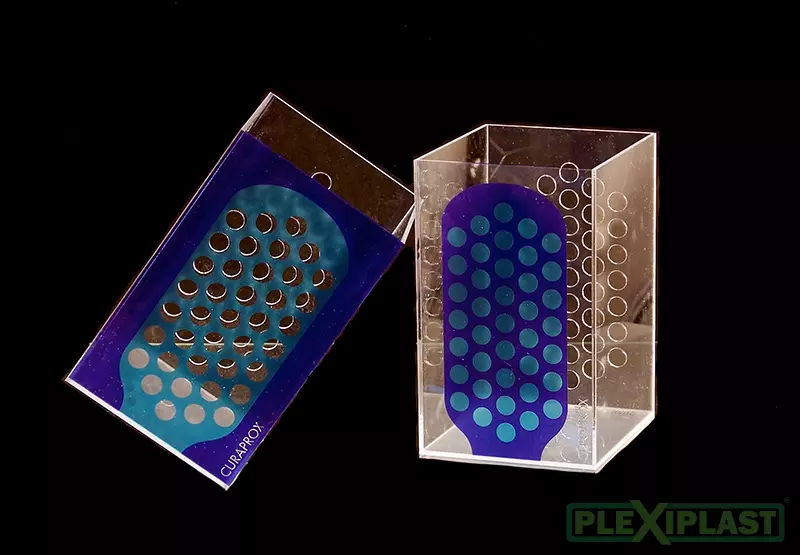

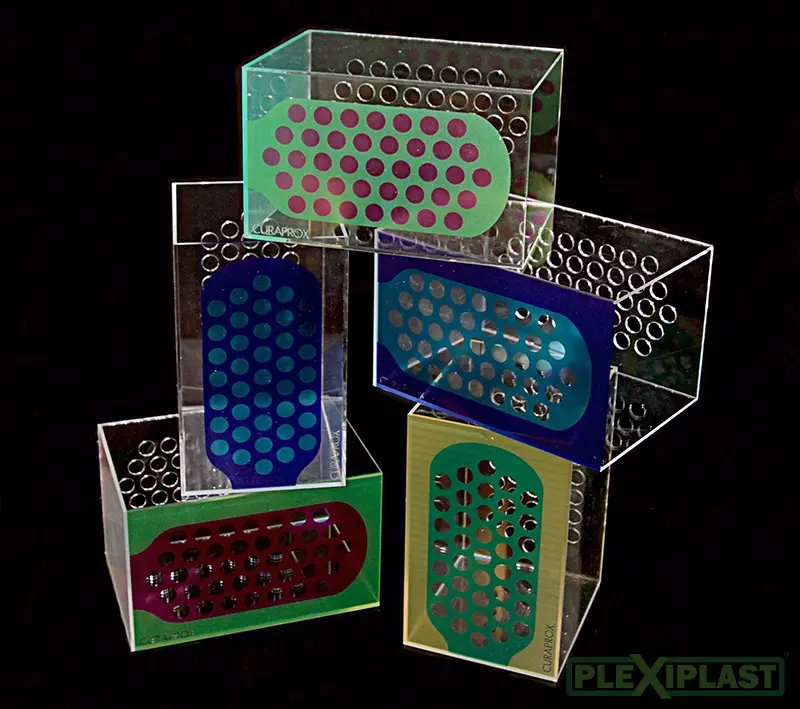

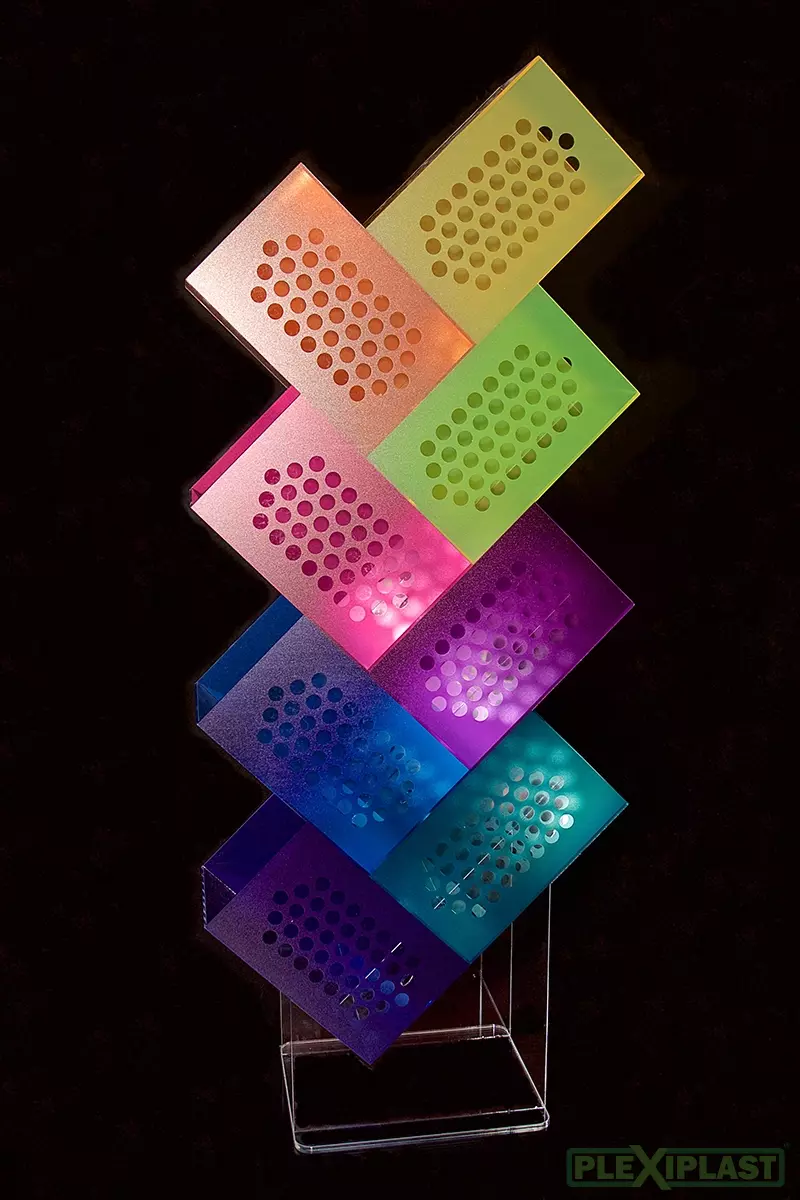

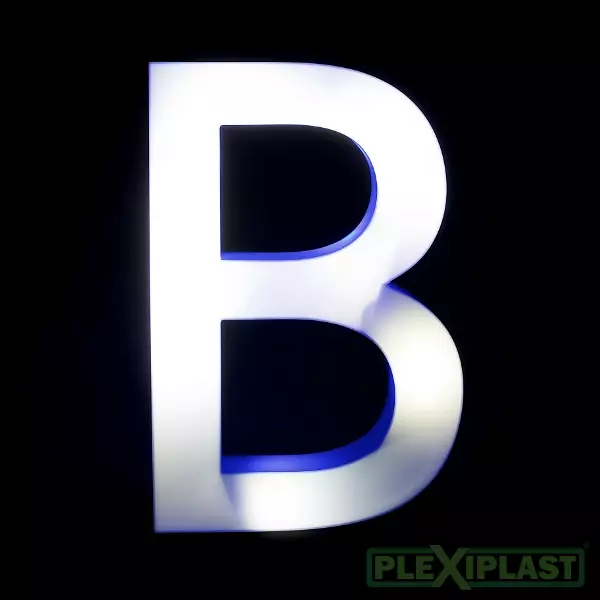

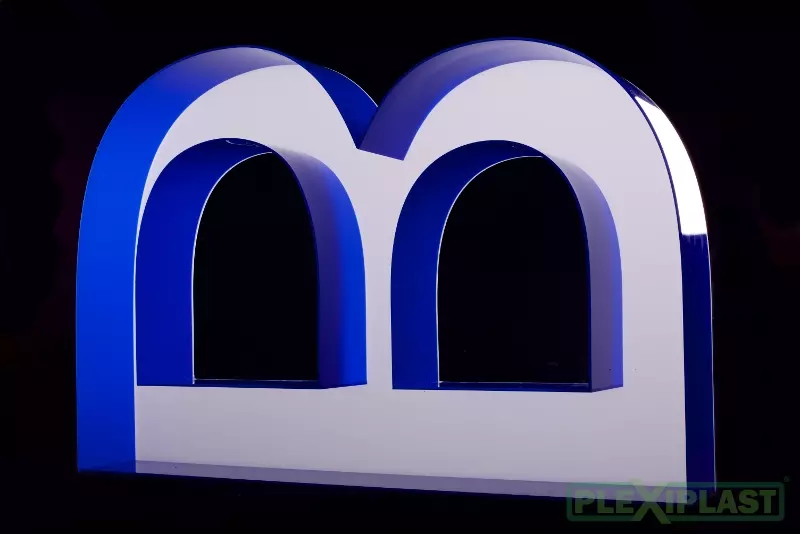

Plexiglas bonding demonstration, Plexiglas products

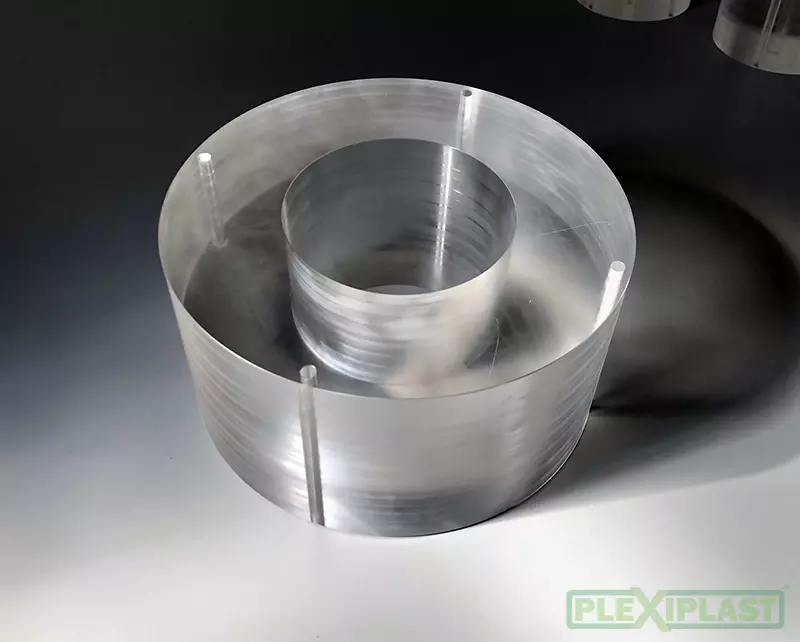

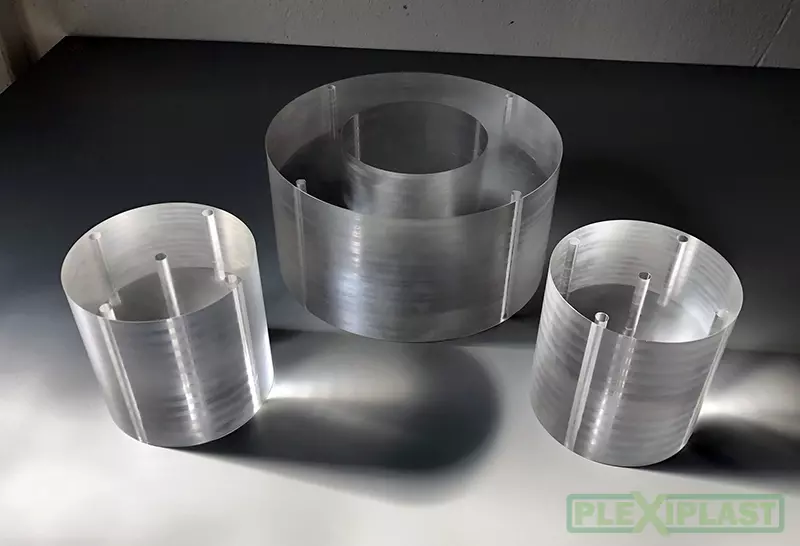

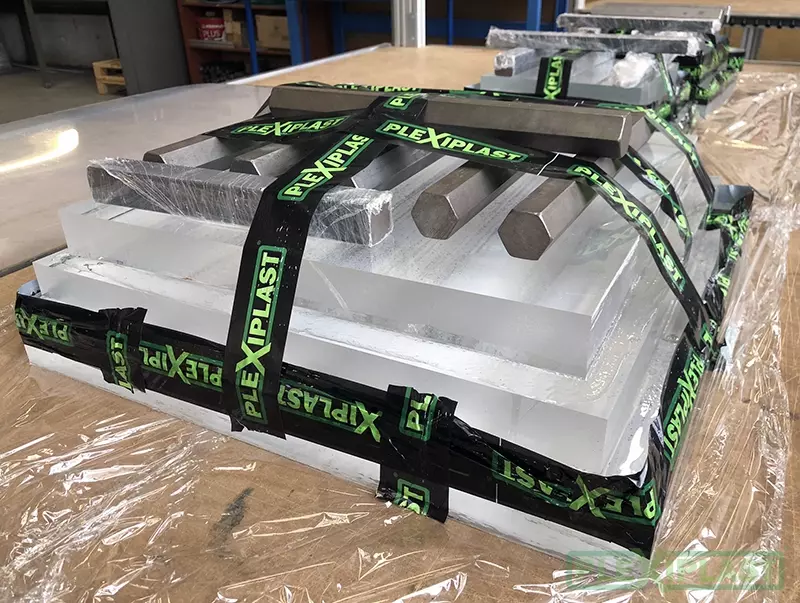

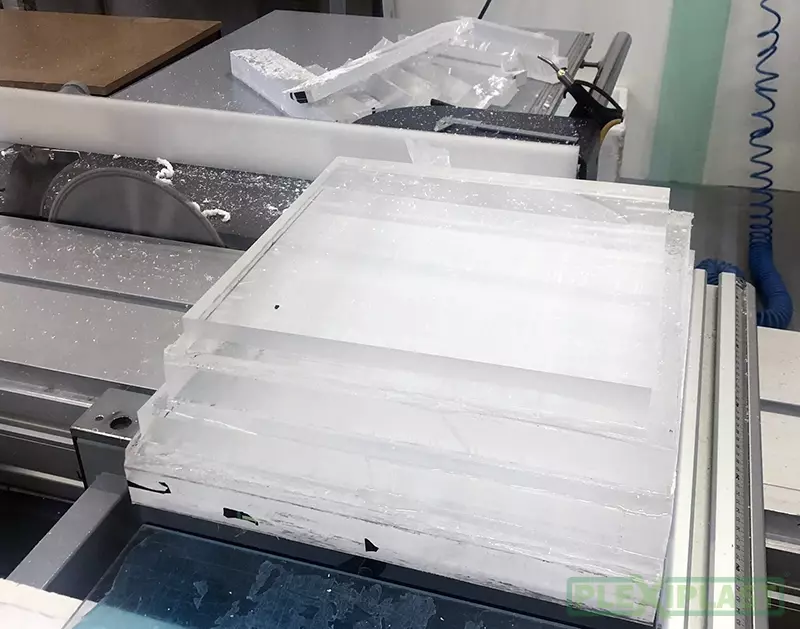

Plate gluing, surface gluing:

We deal with flat bonding of plexiglass material. We are able to glue together different thicknesses (even plexiglass blocks), different colors and layer the material into the desired panel. Often in practice, clear Plexiglas is bonded to colored Plexiglas. This achieves the clear board with the coloured board and the resulting effect is that the thick bonded material looks like all coloured. Only when looking from the side (into the edge) of the material is it apparent that it is a glued joint of coloured and clear Plexiglas. This bonding method is often used because manufacturers of Plexiglas produce coloured sheets in limited thicknesses, most commonly 3 mm.

Demonstration of gluing plexiglass surfaces, flat gluing of plexiglass blocks:

Technical Advisor

Contact our experienced technical advisor to find out all about the prices and processing options for the materials listed

BY PHONE

VIA EMAIL