Frequently Asked Questions

Plexiglas (PMMA) is very sensitive to chemicals and abrasive materials.

It is important to use appropriate cleaning agents and techniques for the treatment (cleaning or washing) of Plexiglas to avoid damaging the surface and structure of the material.

Water and soap (spring cleaner) and a soft microfibre cloth are sufficient for normal cleaning of the Plexiglas. For heavier soiling, specialised cleaners for plastics and Plexiglas can be used, However, cleaners containing LIQUOR, ALCOHOL, solvents and thinners should be avoided.

For resistant contamination we recommend using medical gasoline (pure gasoline) which has a very low oil fraction and therefore does not leave streaks on the surface of the material.

Suitable cleaning products:

- Pure gasoline (medical)

- Technical gasoline

- Water with soap

- Spring water

- Microfibre cloth

Inappropriate cleaning products:

- Lye

- Alcohol

- Petrol cleaner

- Thinners and solvents

- Ammonia (ammonium hydroxide)

- Coarse sponges, brushes, wire brushes, sandpaper

Using any alcohol-based product will cause negative irreversible changes in the structure of the Plexiglas.

The issue of polishing scratches and grooves in Plexiglas is dealt with in the section "Plexiglas polishing" see the link below:

Polishing scratches and grooves.

Information about protective films on material and identification labels can be found here:

Or acrylic (organic) glass is a transparent synthetic polymer (colourless substance) with thermoplastic properties. It resembles glass in its optical properties. It is made of polymethyl methacrylate (from this word also comes the common name acrylate) and is available in many modifications (XT, GS), shapes and colours (clear Plexiglas, coloured Plexiglas). Plexiglas has double-sided UV protection and is therefore suitable for outdoor and indoor use.

Plexiglas panels have high impact strength, up to 10 times higher impact strength compared to glass. It is also 50% lighter than glass. These properties predestine Plexiglas for use in many well-known industries such as advertising (signs, displays, totems, shop fittings, sales displays), construction (barriers, walls), etc.

Sample of plexiglass productsPolycarbonate (PC), is a group of thermoplastic polymers containing carbonate groups in their structure. Polycarbonates have high (to extremely high) impact toughness. It can be used at temperatures from -40°C to +130°C. Polycarbonate also has, like Plexiglas, double-sided UV protection and is available in various colours (clear polycarbonate, bronze polycarbonate). There are also solid sheets (like plexiglass) or chamber sheets (roofing pergolas, terraces, roofs).

Polycarbonate is a soft material that is very tough and impact resistant. Compared to glass and transparent plastics are virtually indestructible. It is therefore used as a safety material, typically for the manufacture of machine housings where there is a risk of objects flying off workpieces, and as window or bus stop panels where there is a greater risk of vandalism. However, the softness of the material is reflected in the possibility of relatively easy damage to the surface of the material, which is more very difficult to remove in most cases.

In contrast, Plexiglas cracks and shatters on impact, but retains its excellent surface properties for longer. Compared to polycarbonate, it is more durable scratch-resistant and generally more resistant to UV radiation. It is therefore mainly used in the production of advertising and promotional items.

There are several ways to glue plexiglass. For example, with a one-component adhesive (simple gluing of which results in a slight appearance of bubbles in the glued joint), two-component glue (more complex bonding procedure which results in a perfect joint). Adhesives are used for bonding Plexiglas ACRIFIX.

On the surface, these materials are indistinguishable from each other, but they have different properties related to the plasticity temperature, different behaviour at technological processing (e.g. blowing, laser engraving, pressing). Generally speaking, cast Plexiglas is of higher quality than extruded Plexiglas.

Cast Plexiglas is more expensive than extruded plexiglass, the difference in price is roughly 20%. Cast Plexiglas has a greater material width tolerance, it is suitable for outdoor use because it can withstand higher temperatures than extruded Plexiglas.

Cast acrylic is typically used for more complex production technology such as sphere and dome blowing.

Extruded Plexiglas is cheaper than cast Plexiglas, this is due to the human labour involved in the production of the raw material. However, this lower price is offset by the lower surface quality and higher susceptibility to the formation of heat-affected areas.

Extruding process leads to re-forming of polymers in length and their narrowing due to high gloss stretching. This causes so called 'granular effect' which leads to shrinkage depending on particular axes positioning during material thermal forming.

Laser cutting of Plexiglas and other non-metallic materials is a common method of material machining that we use extensively. Thanks to the high-power laser, we limit manual formatting of the material and leave this to the laser, which is more efficient and accurate.

CNC milling of plexiglass, milling of polycarbonate is performed on our modern CNC router with a working area of 3100 x 2100 mm. High machine performance allows us to achieve very fast machining times and therefore we are able to charge low prices for plate machining.

CNC milling of material edges is performed on our modern CNC router which is equipped with a vertical table. On this table the workpiece is clamped perpendicular to the spindle which then performs the precise drilling or slotting in the edge of the material. More about this technology and photos from the production can be found by clicking the link at the beginning of the paragraph.

Plexiglas polishing is done in several ways. Our many years of experience allow us to always choose the right way of polishing the material so that the polishing process is gentle on the material structure and the result is satisfactory for the customer.

Edge polishing is done by machine, we use diamond tools for polishing.

Polishing of surfaces or grooves is carried out by flame, manually (with special discs) using abrasive pastes or chemically.

By making and bonding of Plexiglas covers and diorama covers have been in business since the beginning of our existence. We offer many variants of production (glued, bent), different types of glue (simple one-component glue, or more complex two-component gluing). We are able to produce small and large covers.

Glued diorama covers - glued from 5-part plexiglass panels.

Bent diorama covers - front and back bent, sides glued.

The answer is not clear. Some yes, some no. Most shields cannot be polished, they are made of a different material (injection moulding material) than "regular" plexiglass, some shields are also made of polycarbonate containing styrene, which makes the plexiglass less polishable. the treatment of the shield. If an inappropriate cleaning agent containing alcohol has been used on the shield, polishing is almost impossible (the material becomes brittle when exposed to alcohol, the polishing the plastic often cracks).

Bending plexiglass or polycarbonate we perform either by local heating of the material plate or by flat heating in a tempering furnace (arc bending). Our bending machines are able to bend up to 4 bends at a time, ensuring that the the material from both the bottom and the top side. We are able to locally heat bend plexiglass to a thickness of up to 20 mm.

Mechanical blasting of materials is performed in a sandblasting chamber using high pressure and fine material (substrate, We make the sandblasting templates ourselves on our CNC laser. The result of the cooperation of individual departments results in sandblasted logos, motifs or inscriptions. We also sandblast the edges material, for example letters, or machine matting of straight edges.

All requests for custom manufacturing should be followed with picture or drawing of desired product to avoid miscommunication. We can process these formats:

- .dwg a .dxf - Auto Cad

- .ai - Adobe Ilustrator

- .jpg - picture

Acrylic

Bending radius that material safely withstands is calculated with this formula:

R [mm]= l[mm] * 330, where l = material thickness;

Examples of use:

5mm thick acrylic: R = 5 * 330 = 1650mm (circle diameter of 3300mm). 5mm thick acrylic can be bent without damage into radius of R=1650mm or in circle of 3300mm diameter.

Polycarbonate

Bending radius that material safely withstands is calculated with this formula:

R [mm]= l[mm] * 150, where l = material thickness;

Examples of use:

Polycarbonate 5 mm thick: R = 5 * 150 = 750mm (circle diameter 1500mm). Polycarbonate 5mm thick can be bent in radius up to R=750mm without any damage, or in circle of 1500mm diameter

For drilling of acrylic sheets we supply can be used any standard threaded wood drills. We recommend not to put excessive pressure on the drill and use higher (not high) revolutions.

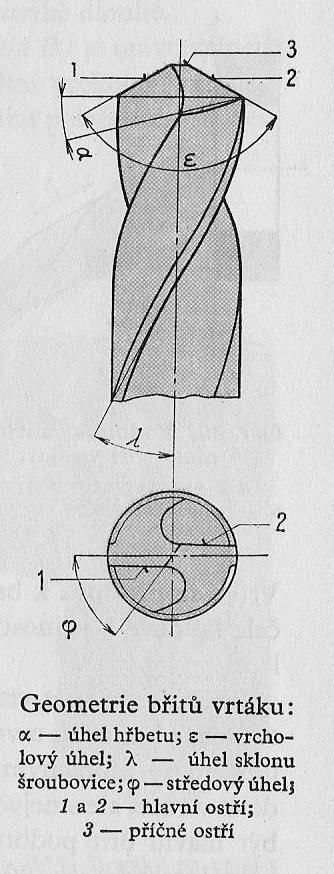

For easier drilling it is better to adjust the drilling bit to zero angle of the drill head (marked as α in the picture), see picture below:

For drilling of deep holes or edge holes we recommend to use coolant (e. g. water) and apply frequent plastic chip removal.