Bending Plexiglas and Polycarbonate

Bending Plexiglas (Plexiglas XT, Plexiglas GS) and polycarbonate (PC) is one of the most effective methods of shaping these plastic materials for a wide range of applications - from advertising displays, covers and design elements to industrial components.

How does the bending process work?

The process of bending Plexiglas and bending polycarbonate is carried out by means of controlled heating of the material in a precisely defined area. Once the required temperature is reached, the material is bent to the desired angle or shape. Once cooled, the plastic retains its new shape without compromising strength or transparency.

According to the size of the material to be heated, bending is divided into specific types:

- Bending by local annealing

- Bending by full-area annealing

We commonly bend materials by local annealing:

- bending of Plexiglas XT and GS - material suitable for presentation elements

- PC polycarbonate bending - suitable for technical parts and safety guards

- bending PET-G and A-PET - material with high chemical resistance

- Bending of forex and foamalux (lightweight PVC)

- Bending of polypropylene plates,

Why cooperate with PLEXIPLAST?

PLEXIPLAST - precision in every detail.- Our many years of experience make us one of the market leaders in Europe.

- Our own production - everything is handled directly by us, without intermediaries.

- Flexibility - small and large series, prototypes and custom solutions.

- Quality - consistent output control.

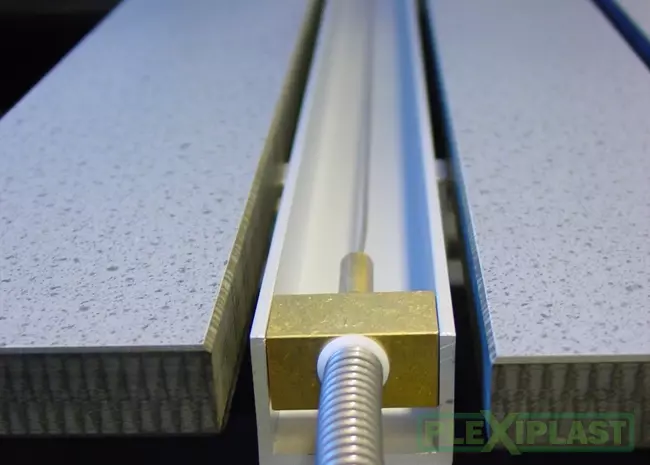

Demonstration of our equipment for local heating of plastic sheet material

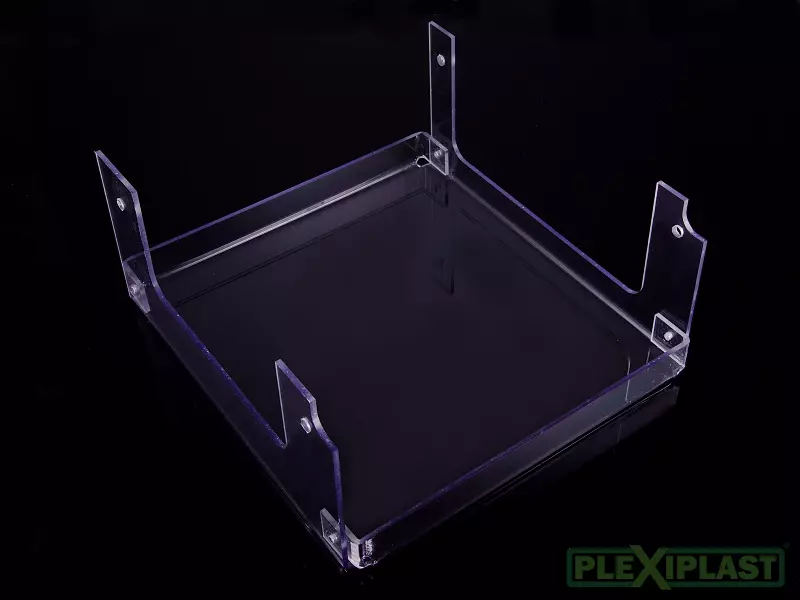

Plexiglas bending, polycarbonate bending, product demonstrations:

Plate bending, bending of plastics into curves

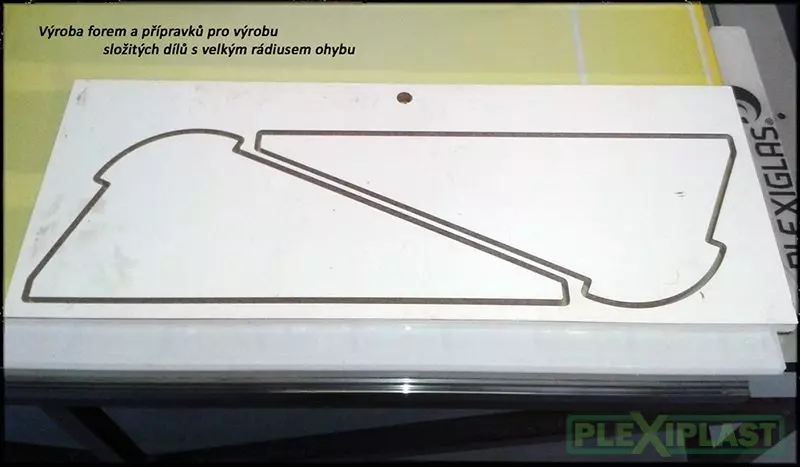

Flat bending of plexiglass and polycarbonate (generally thermoplastics) is considerably more complex, but not unrealistic. In this type of bending, a plate of material is placed in a special tempering oven. The shaping of the material in the furnace is ensured by a pre-made positive or negative mould into which the material slowly lays and copies this mould. This achieves an arc radius according to the produced mould (copying of the mould arc by the material). The material is not heated locally, but all over.

We make all the moulds for the production of complex bent parts ourselves. Our years of experience allow us to make the appropriate choice of mould production (positive or negative mould) to achieve the correctness of the desired shape (curve) in the best possible manufacturing tolerance.

Flat bending of plexiglass and polycarbonate, bending in a tempering oven:

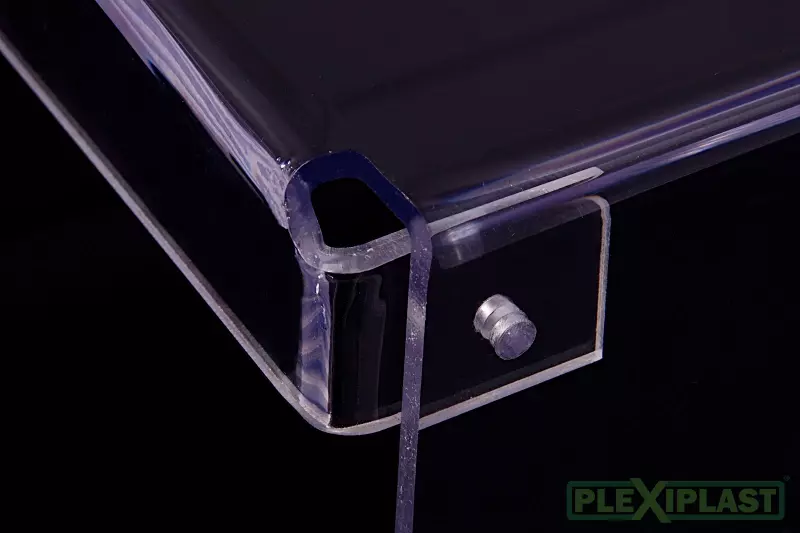

Acrylic bending principle

If we bend acrylic with short overlap, say 30mm, deflection occurs.

Deflection is caused by local heat treatment and subsequent tension within material after flexion.

Acrylic drying

Acrylic and polycarbonate are known for their negative feature and that is they spontaneously absorb air humidity. Acrylic materials must be dried in furnaces before bending to avoid bubbles once locally heat treated for bending.

Technical Advisor

Contact our experienced technical advisor to find out all about the prices and processing options for the materials listed

BY PHONE

VIA EMAIL