Sale and processing of continuous cast acrylic

Perspex® CC - Continuous cast acrylic

Perspex® CC is a plexiglass manufactured by a special method casting process on a production belt, which provides a more efficient production process than the traditional method of cast Plexiglas with a stable material strength. As a result, Perspex® continuously cast Plexiglas in compared to conventional cast Plexiglas, it is more suitable for the production of bonded parts and joints. Read more advantage is also the speed and precision in heat treatment and the distinctive appearance of the material after laser engraving.

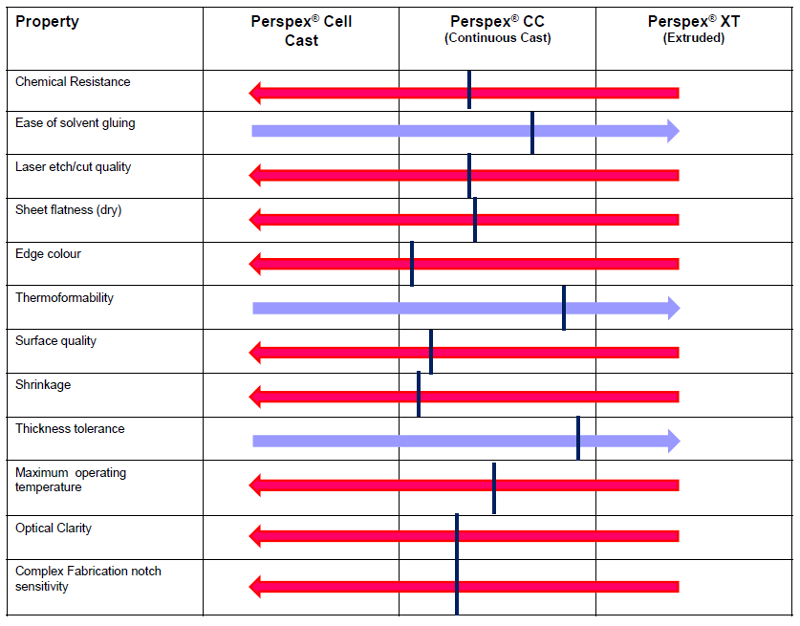

Compared to conventional extruded material, continuously cast Plexiglas is characterized by a higher chemical resistance, it is robust in processing, in particular it does not overheat during machining. Its optical properties are also significantly improved, including its expressiveness laser engraving, plate edge colour and optical clarity, including lower incidence of surface defects in material and associated surface gloss. Improved material heating properties are also significant, Perspex® is significantly more dimensionally stable in tests compared to extruded Plexiglas.

Continuous cast acrylic features compared with common cast and extruded acrylic in following chart:

Continuous cast acrylic Perspex® CC is available in wide variety of colors. For basic idea see our sampler:

Perspex® CC production

We sell and custom process continuous cast acrylic Perspex® CC purchased with us. Items made o cast acrylic can be mainly found in advertising, construction and exhibition industry.

Most commonly custom manufactured Perspex® CC products for our clients are:

- illuminated panels with engraved inscriptions

- noise barrier walls and dividing plates

- balcony and staircase panels

- terrace roofing, balcony roofing

- acrylic boat windows, acrylic RV windows

- acrylic lamps, lamp shields, lighting

- vacuum formed parts

Contact us to get a free price offer